At UNIOR's Forge Program, we have launched a new robotized forging line L-6, which will significantly contribute to the company's competitive growth and help maintain its market position in the field of forging production.

Purpose and Goals of the New L-6 Line

The project's objective was to establish a fully robotized (autonomous) forging line, ensuring high quality and production efficiency of forgings.

Key goals of the L-6 line include:

• Increasing production capacity, with annual production expected to exceed 2 million forgings,

• Ensuring high forging quality,

• Reducing the forging process rejection rate to less than 4%.

Added Value and Innovative Solutions

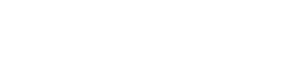

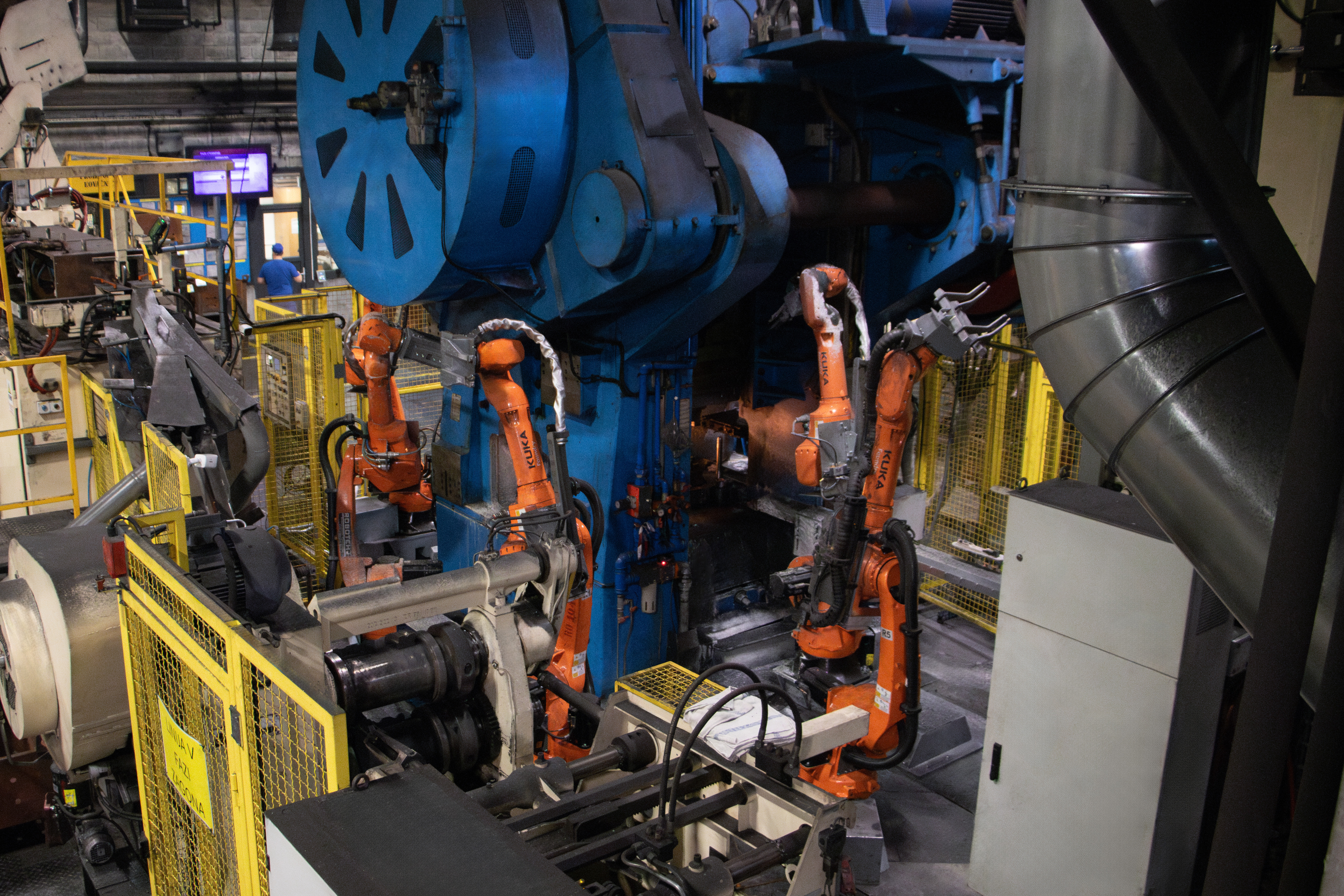

The new L-6 forging line also enables the acquisition of specific experience and knowledge, which will be crucial for future development projects of the company. Through this project, we have implemented the latest technology, such as a powerful Clearing mechanical press with a nominal forming force of 2,000 tons. This is the first autonomous robotized forging line, featuring seven industrial robots and a new, advanced lubrication system operated by a robot. We have also developed and implemented an innovative gripping and part-handling system, which will significantly enhance the efficiency and precision of our production process. The project was carried out in cooperation with renowned companies such as Fellner GmbH (quick-change tooling), Bemers GmbH (lubrication system), and Roboteh (robotization), ensuring the highest standards of quality and technological innovation.

UNIOR – Development with a Focus on Innovation

With the implementation of the L-6 forging line, UNIOR not only ensures continued growth and competitiveness in the global market but also strengthens its position as a leading international company in the forging industry. Currently, UNIOR operates with more than 60 robots, and with this project, we are setting new milestones in automation, robotization, and optimization of production processes.

About UNIOR

UNIOR d.d. is one of Europe’s leading companies in the field of forging and tool production, with over a century-long tradition of quality and innovation. By investing in the development and automation of processes, UNIOR ensures long-term competitiveness and sustainable growth. We are a leader in the industry, with key competencies in the processes of closed-die steel forging, aluminum forging, cold forging, and the machining of our own forgings, as well as sintering. Our products are crucial for renowned automotive brands such as Porsche, BMW, Audi, Bentley, Jaguar, and others, as well as for Tier 1 and Tier 2 system suppliers.

Corporate communications department